Kinetix

We engineered an innovative and patented impact attenuation system that will revolutionize head safety across multiple industries.

With Kinetix we eliminated straps and padding and replaced them with simple machines.

Simple machines offer more variables that can be optimized to handle the rigors of an impact to the head.

Our machines are matched to individual helmet shells and engineered for superior impact attenuation.

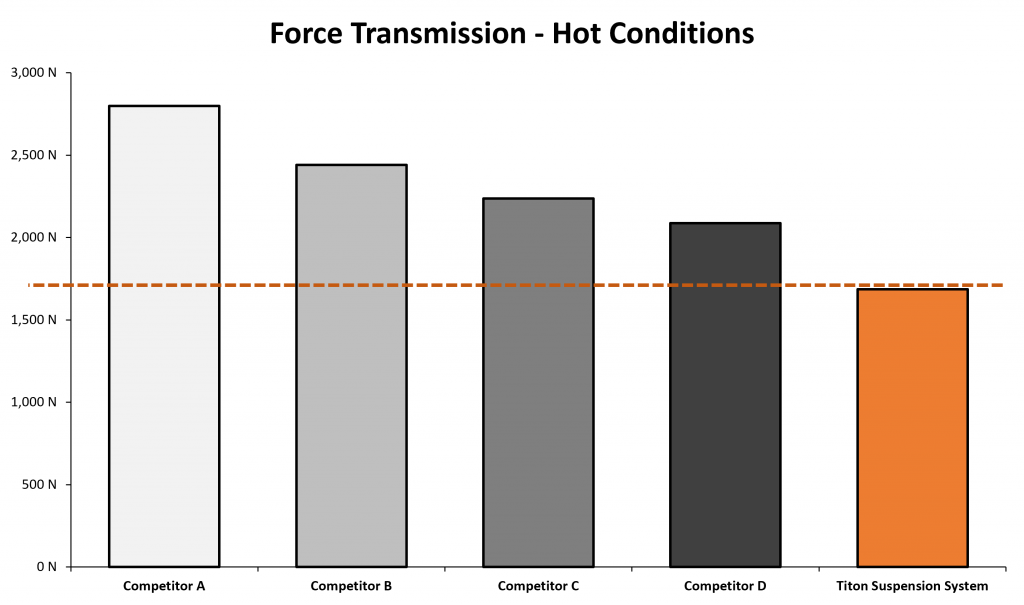

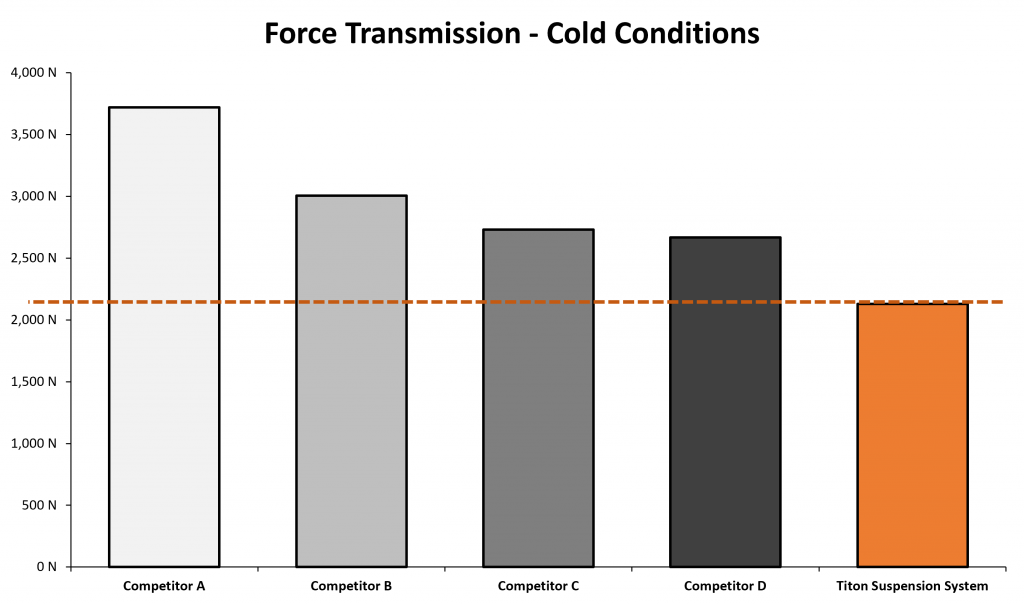

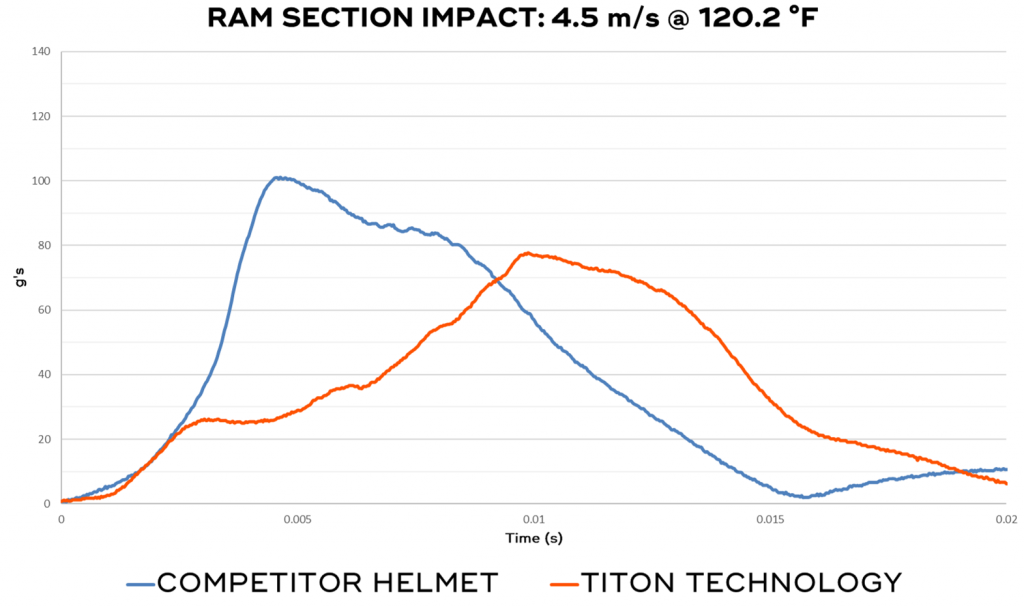

When an impact occurs, helmets with Kinetix technology transmit less force and acceleration to the user’s head and neck compared to ordinary helmets in the same industry and, on average, a force 50% lower than what international standards require.

**Different applications will vary the impact absorption capabilities of the suspension; this average is calculated from our most developed systems and across a range of temperature conditions

How does it work?

Typical Suspensions

A typical helmet system is made of a strong outer shell and inner suspension (straps and/or padding)

At the time of an impact, the suspension accommodates to the head and deforms, along with the outer shell, in order to absorb energy.

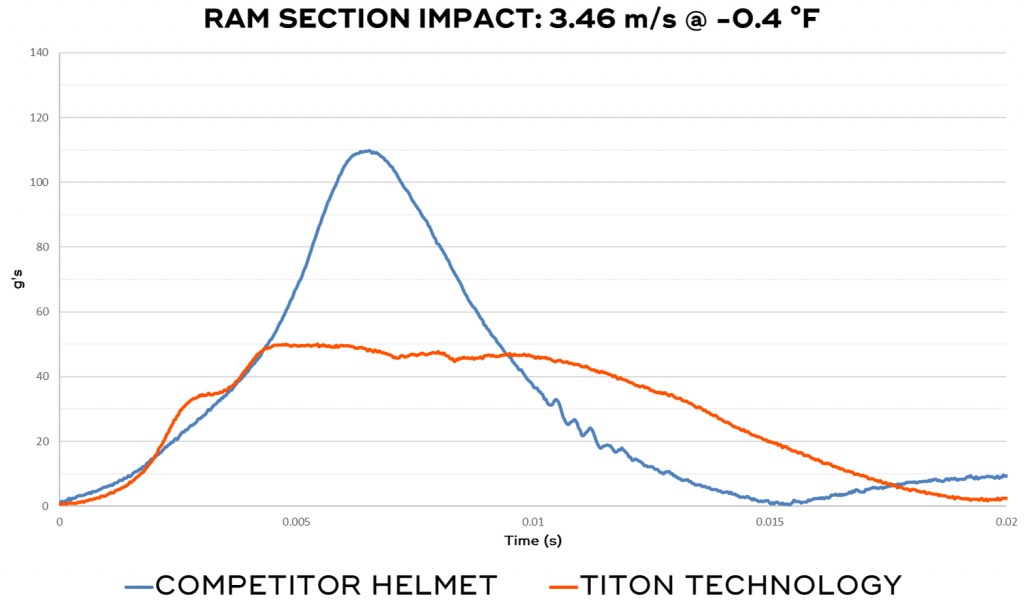

As a result, an ordinary helmet absorbs energy much like a spring would, by compressing itself against the head, demanding ever increasing amounts of force to deform. This force is directly transmitted to a users head and spine.

Kinetix Suspension

Titon Technology incorporates machinery to helmet shells.

Kinetix controls the way energy is absorbed and dissipated during an impact, which result in lower forces being transmitted a user’s head and spine.

Lever rotation allows:

- Modification of the magnitude and direction of impact forces.

- Stretching springs perpendicularly to the impact direction for optimal energy absorption and dissipation.

The combination of these effects results in reduction of the impact forces being transmitted to a user which gives our system a superior performance.

Kinetix Superior Results

Most helmets in the market today are created to comply with national safety standards, such as ANSI/ISEA for industrial and NOCSAE for sports, but not all helmets that comply with a standard provide the same level of safety. Small differences in performance, as measured by standard testing, can mean huge differences in safety. Our system demonstrates huge differences in results that translate to greater safety.

Industrial Type 1 Hard Hats

Football

Kinetix Now Available!

You can find our Kinetix suspension inside HexArmor® Ceros® XA250 helmet.